Columbia University Libraries Digital Collections: The Real Estate Record

Use your browser's Print function to print these pages.

Real estate record and builders' guide: v. 85, no. 2201: May 21, 1910

Text version:

Please note: this text may be incomplete. For more information about this OCR, view About OCR text.

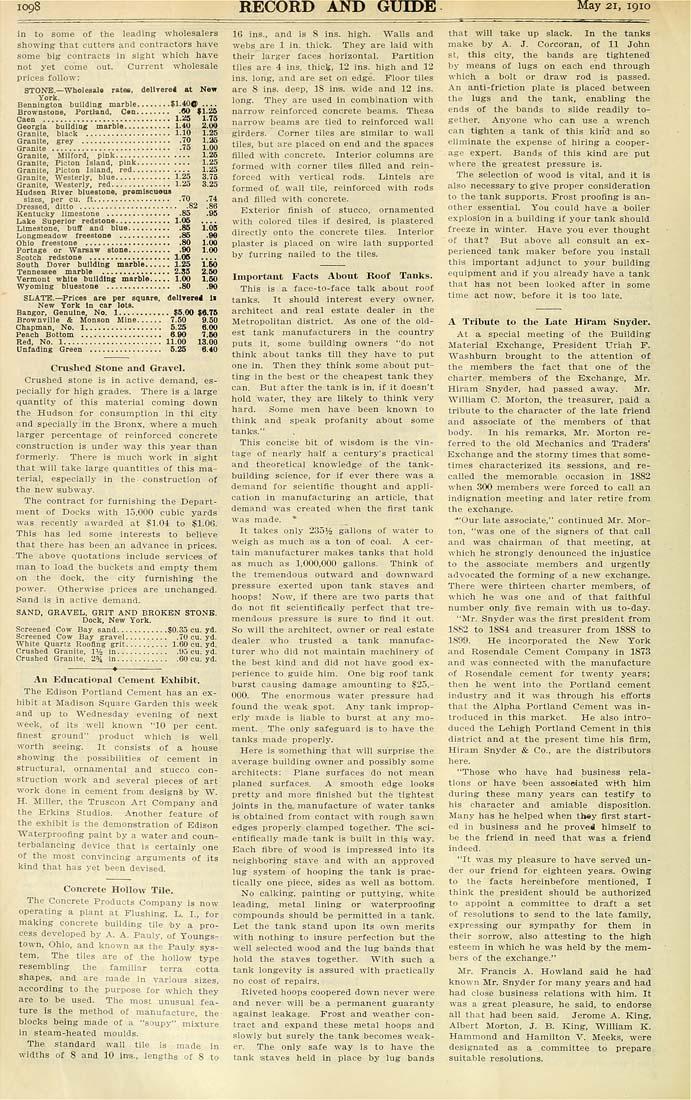

I09S RECORD AND GUIDE May 21, 1910 in to some of the leading wholesalers showing that cutters and contractors have some big contracts in sight which have not yet come out. Current wholesale prices follow: STONE.—Wholeaalo ratee, dellvere* at New York. Bennington building marble........$1.40© ,.,, Brownstone, Portland, C»n.........80 $1.25 Caen.............................. 1.23 1.73 Georgia building marble........... 1.40 2,00 Granite, black .................... 1.10 1.25 Granite, grey ......................70 1,26 Granite .............................75 1.00 Granite, Milford. pink................. 1.25 Granite, Picton Islaud, pink............ 1.25 Granite, Picton Island, red............. 1,25 Granite, Westerly, blue............. 1.25 3,75 Granite. Westerly, red.............. 1.25 3.25 Hudson River bluestoQe, promlscuoua sizes, per cu. ft...................70 .74 Dressed, ditto ........................82 ,86 Kentucky limestone ................85 ,95 Lake Superior redstone............. 1.05 .... Limestone, buff and blue...........85 1.03 Longmeadow freestone .............85 .90 Obio freestone .....................80 1.00 Portage or Warsaw stone...........90 1,00 Scotch redstone ...................1.06 .... South Dover building marble......1,25 1.60 Tennessee marble ................2,S3 2.S0 Vermont white building marble..... 1,00 1,50 Wyoming bluestone ................80 ,90 SLATE,—Prices are per square, deliverei li New York In car lots. Bangor, Genuine. No, 1............$5.00 56,73 Brownville & Monson Mine...... 7.50 9.50 Chapman. No. 1.................. 5.25 6.00 Peach Bottom ................... 6.90 7.B0 Red, No. 1....................... 11.00 13.00 Unfading Green ................. 6.25 6.40 Ciiished Stone and Gravel. Crushed stone is in active demand, es¬ pecially for high grades. There is a large quantity of this material coming down the Hudson for consumption in thi city and specially in the Bronx, where a much larger percentage of reinforced concrete construction is under w^ay this year than formerly. There is much work in sight that will take large quantities of this ma¬ terial, especially in the- <;oii struct ion of the new subway. The contract for furnishing the Depart¬ ment of Docks with 15,000 cubic yards was recently awarded at $1.04 to $1.06. This has led some interests to believe that there has been an advance in prices. -The above quotations include services of man to load the buckets and empty them on the dock, tbe city furnishing the power. Otherwise prices are unchanged. Sand is in active demand, SAND, GRAVEL, GRIT AND BROKEN STONE. Dock. New York, Screened Cow Bay sand............$0.35 cu. yd. Screened Cow Bay gravel...........70 cu, yd. White Quartz Roofing grit.......... 1.60 cu, yd. Crushed Granite, I'A in.............95 cu. yd. Crushed Granite, 2^ in.............60 cu. yd. ------------------■-----------------------------------------------*------------------------------------------------------------------- All Educational Cement Exhibit. The Edison Portland Cement has an ex¬ hibit at Madison Square Garden this week and up to Wednesday evening of next week, of its well known "10 per cent, finest ground" product which is well worth seeing. It consists of a house showing the possibilities of cement in structural, ornamental and stucco con¬ struction work and several pieces of art work done in cement from designs by W, H, Miller, the Truscon Art Company and the Erkins Studios. Another feature of the exhibit is the demonstration of Edison Waterprooflng paint by a water and coun¬ terbalancing device that is certainly one of the most convincing arguments of its kind that has yet been devised. Concrete Hollow Tile. The Concrete Products Company is now operating a plant at Flushing, L, L, for making concrete building tile by a pro¬ cess developed by A. A. Pauly, of Youngs- toivn, Ohio, and known as the Pauly sys¬ tem. The tiles are of the hollow type resembling the familiar terra cotta shapes, and are made in various sizes, according to the purpose for which they are to be used. The most unusual fea¬ ture is the method of manufacture, the blocks being made of a "soupy" mixture in steam-heated moulds. The standard wall tile is made in widths of 8 and 10 Ins., lengths of 8 to 16 ins,, and is S ins, high. Walls and webs are 1 in. thick. They are laid with their larger faces horizontal. Partition tiles are 4 ins, thick, 12 ins, high and 12 ins, long, and are set on edge. Floor tiles are 8 ins, deep, IS ins. wide and 12 ins. long. They are used in combination with narrow reinforced concrete beams. These narrow beams are tied to reinforced wall girders. Corner tiles are similar to wall tiles, but are placed on end and the spaces filled with concrete. Interior columns are formed with corner tiles filled and rein¬ forced with vertical rods. Lintels are formed of wall tile, reinforced with rods and fllled with concrete. Exterior finish of stucco, ornamented with colored tiles if desired, is plastered directly onto the concrete tiles. Interior plaster is placed on wire lath supported by furring nailed to tbe tiles. luipoi-tant Pacts About Roof Tanks. This is a face-to-face talk about roof tanks. It should interest every owner, architect and real estate dealer in the Metropolitan district. As one of the old¬ est tank manufacturers in the country puts it, some building owners "do not think about tanks till they have to put one in. Then they think some about put¬ ting in the best or the cheapest tank they can. But after the tank is in, if it doesn't hold "water, they are likely to think very hard. Some men have been known to think and speak profanity about some tank's." This concise bit of wisdom is the vin¬ tage of nearly balf a century's practical and theoretical knowledge of the tank- building science, for if ever there was a demand for scientific thought and appli¬ cation in manufacturing an article, that demand was created when the first tank was made. * It takes only 235^ gallons of water to weigh as much as a ton of coal, A cer¬ tain manufacturer makes tanks that hold as much as 1,000,000 gallons. Think of the tremendous outward and downward pressure exerted upon tank staves and hoops! Now. if there are two parts that do not fit scientifically perfect that tre¬ mendous pressure is sure to find it out. ,So W'ill the arciiitect. owner or real estate dealer who trusted a tank manufac¬ turer who did not maintain machinery of the best kind and did not have good ex¬ perience to guide him. One big roof tank burst causing damage amounting to .^"25,- 000. The enormous water pressure had found the weak spot. Any tank improp¬ erly made is liable to burst at any mo¬ ment. The only safeguard is to have the tanks made properly. Here is 'something that will surprise the average building owner and possibly some architects: Plane surfaces do not mean planed surfaces. A smooth edge looks pretty and more finished but the tightest joints in the. manufacture of water tanks is obtained from contact with rough sawn edges properly clamped together. The sci¬ entifically made tank is built in this way. Each fibre of wood is impressed into its neighboring stave and with an approved lug system of hooping the tank is prac¬ tically one piece, sides as well as bottom. No calking, painting or puttying, white leading, meta! lining or waterproofing compounds should be permitted in a tank. Let the tank stand upon its own merits with nothing to insure perfection but the well selected wood and the lug bands tbat hold the staves together. With such a tank longevity is as'sured with practically no cost of repairs. Riveted hoops coopered down never were and never will be a permanent guaranty against leakage. Frost and weather con¬ tract and expand these metal hoops and slowly but surely the tank becomes weak¬ er. The only safe way is to have the tank staves held in place by lug bands that will take up slack. In the tanks make by A. J, Corcoran, of 11 John st, this city, the bands are tightened by means of lugs on each end through which a bolt or draw rod is passed. An anti-friction plate is placed between the lugs and the tank, enabling the ends of the bands to slide readily to¬ gether. Anyone who can use a wrench can tighten a tank of this kind and so eliminate the expense of hiring a cooper¬ age expert. Bands of this kind are put where the greatest pressure is. The selection of wood is vital, and it is also necessary to give proper consideration to the tank supports. Frost proofing is an¬ other essential. You could have a boiler explosion in a building if your tank should freeze in winter. Have you ever thought of that? But above all consult an ex¬ perienced tank maker before you install this important adjunct to your building equipment and if you already have a tank that has not been looked after in some time act now, before it is too late. A Tribute to the Late Hirani Snyder. At a special meeting of the Building Material Exchange, President Uriah F. Washburn brought to the attention of tbe members the fact that one of the charter, members of the Exchange, Mr. Hiram Snyder, had passed away. Mr. William C. Morton, the treasurer, paid a tribute to the character of the late friend and associate of the members of that body. In his remarks, Mr. Morton re¬ ferred to the old Mechanics and Traders' Exchange and the stormy times that some¬ times characterized its sessions, and re¬ called the memorable occasion in 1882 when 300 members were forced to call an indignation meeting and later retire from the exchange, "Our late associate," continued Mr. Mor¬ ton, "was one of the signers of that call and was chairman of that meeting, at which he strongly denounced the injustice to the associate members and urgently advocated the forming of a new^ exchange. There were thirteen charter members, of which he was one and of that faithful number only five remain with us to-day, "Mr, Snyder was the first president from 1SS2 to 1SS4 and treasurer from ISSS to 1809. He Incorporated the New York and Rosendale Cement Company in 1873 and was connected with the manufacture of Rosendale cement for twenty years; then he went into the Portland cement industry and it was through his efforts that the Alpha Portland Cement was in¬ troduced in this market. He also intro¬ duced the Lehigh Portland Cement in this district and at the present time his firm, Hiram Snyder & Co., are the distributors here, "Those who have had business rela¬ tions or have been associated wrth him during these many years can testify to his character and amiable disposition. Many has he helped when thay first start¬ ed in business and he proved himself to be the friend in need that was a friend indeed. "It was my pleasure to have served un¬ der our friend for eighteen years. Owing to the facts hereinbefore mentioned, I think the president should be authorized lo appoint a committee to draft a set of resolutions to send to the late family, expressing our sympathy for them in their sorrow, also attesting to the high esteem in which he was held by the mem¬ bers of the exchange." Mr. Francis A. Howland said he had known Mr, Snyder for many years and had had close business relations with him. It was a great pleasure, he said, to endorse all that had been said. Jerome A. King. Albert Morion, J. B. King, William K. Hammond and Hamilton V. Meeks, were designated as a committee to prepare suitable resolutions. i