Please note: this text may be incomplete. For more information about this OCR, view

About OCR text.

224

RECORD AND GUIDE

January 31, 1914

piiiii^^

BUILDING MANAGEMENT

SOFT COAL FOR HEATING IS ECONOMICAL, EFFICIENT

AND PRACTICABLE WITH SMOKELESS BOILERS.

By J. F. MUSSELMAN, M. E.

Consulting Engineer.

a

m Conducted by Raymond P. Roberts, Building Manager for the American Real Estate Co.

llllillllllM^^^^^^^^ .....■■■^^^^^^^^^ ......■■■■I.....liillliiililiiliililllilll......■■■■■■IP

WHEN consideration is given to the

fact that for every one thousand

cubic feet of contents of the average

New York office building, loft or apart¬

ment house, somewhere between ¥1 and

$2.50 is spent per year for the coal

burned in the heating apparatus, it is

easy to realize what a large per cent

in the operating cost of any enterprise

goes to the coal bill. With this in mind,

it is difficult to understand why, in de¬

signing the heating systems of buildings,

so little attention is given to the selec¬

tion of the boilers and the determination

of the character of coal to be used. This

is especially remarkable in view of the

fact .that it can be demonstrated that

this item of coal cost is subject to a

variation of at least 40 per cent., which

variation can be traced directly to cor¬

rect or faulty boiler selection or to the

use of right or wrong kind of coal.

A mistake of this kind, once made, is

rarely corrected, for few owners know

what their coal cost really is, and even

fewer can make an accurate estimate of

what it should be. Then this question

of coal cost is apt to come up in mid¬

winter, which is the worst possible time

to think seriously about a change in the

boiler plant. But a boiler that will save

40 per cent, of the coal cost will pay

for itself in from two and one-half to

three years.

Wide Variation in Coal and Its Cost.

So little attention has been given to

the selection of boilers in many of the

present-day buildings that the matter has

generally resolved itself into a condition

by which the boiler of the best sales¬

man or the cheapest manufacturer is

used. This again has brought about the

widest possible variation in the kind and

size of coal used, until it is not uncom¬

mon to see the best grade of stove or

egg coal, which costs on an average $6.25

per ton, used in one building, while an

adjoining building of the same kind is

using No. 1 buckwheat at 13.50 per ton.

The cheapest anthracite coal that can

be used readily under the natural draught

conditions which obtain in the usual

building are pea size, costing in the New

York market an average of about $4.75

per ton, and No. 1 buckwheat, costing

about $3.50. The former has a heat

value of about 12,000 British thermal

units per pound, while the latter runs

in the neighborhood of 11,500 British

thermal units per pound. These twq

sizes are the ones in most general use.

Merits of Soft Coal.

According to the reports of the U. S

Bureau of Mines, there is to be found

in the coal fields of Pennsylvania, Mary¬

land and West Virginia bituminous and

semi-bituminous coal in almost unlim¬

ited quantities. This coal is usually

mined, I am told, on a royalty basis of

ten cents per ton, and the freight is suffi¬

ciently low to allow it to sell in the Mew

York market at $3.75 per ton or less.

These soft coals of the Eastern fields

have very high heating values per pound

and are correspondingly low in ash.

Their average heating value of "run-

of-mine" size is about 14,100 British

thermal units per pound, and, inasmuch

as they are coking, very little fuel is lost

through the grate.

The primary objection to soft coal is

of course, the fact that it smokes, and

we often hear the statement- that the

smoke ordinances of New York will not

permit its use. But this statement is

not correct, and we must consider that

a great many cities which have smoke

ordinances fully as strict as those ot

New York have no hard coal available

at prices not prohibitive.

The importance of abatement of the

smoke nuisance is so manifest and the

economy which could be effected by the

use of this extensive supply of soft coal

so apparent that the U. S. Geological

Survey has authorized an exhaustive in¬

vestigation and test on plants of various

kinds in which soft coal is used. A

report of these tests by Messrs. D. T.

Randall and H. W. Weeks is issued by

the Department of Mines, Bulletin No.

40. The plants which were tested were

equipped with different kinds of stokers,

dutch ovens, down-draft furnaces and

ordinary flat grates. A brief summary

of the conclusions reached states that

smoke prevention is both possible and

economical, and that there are maiiy

types of furnaces and stokers that will

burn soft coal economically without

smoke.

For an ordinary low-pressure heating

plant which is not in conjunction with a

power plant, a mechanical stoker is toe

complicated and too expensive to be

generally used. As it is the purpose of

this article to deal with the conditions

of less expensive and smaller buildings

where isolated plants are not warranted,

the relative merits of mechanical stokers

will not be taken up.

A successful boiler for this kind of

building must be inexpensive, economi¬

cal, smokeless and simple to operate. It

should have a large firebox in order tha^

a considerable quantity of fuel can be

fired at one time, for it is often incon¬

venient, especially in the smaller installa¬

tions, to attend the fire oftener than once

every two hours. It is most important,

too, that such a boiler should have a

large steam space and should be con¬

structed in such a way as to eliminate

as nearly as possible the chance of unex¬

pected breakdown, which might make

the whole system inoperative.

Burns Soft Coal with Almost No Smoke.

This last heating season has intro¬

duced into New York a type of boiler

that accomplishes all of these require¬

ments admirably. It consumes the soft

coal so perfectly that almost no smoke

is visible at the chimney, and at the

same time shows a boiler efficiency aver¬

aging about 2() per cent, higher than the

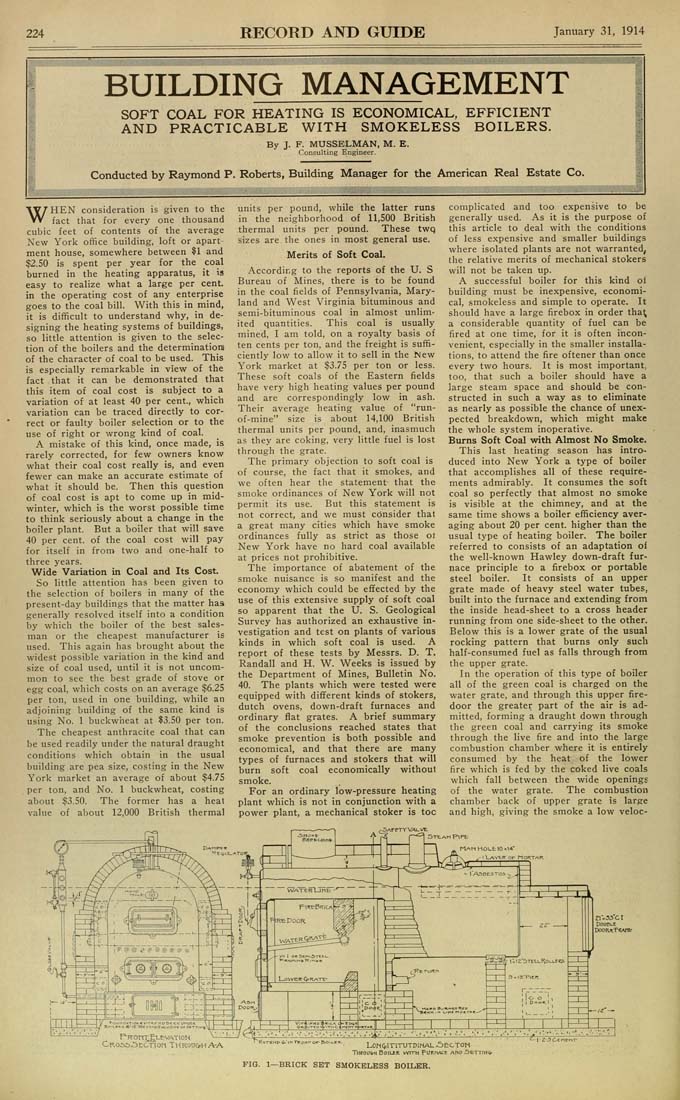

usual type of heating boiler. The boiler

referred to consists of an adaptation of

the well-known Hawley down-draft fur¬

nace principle to a firebox or portable

steel boiler. It consists of an upper

grate made of heavy steel water tubes,

built into the furnace and extending from

the inside head-sheet to a cross header

running from one side-sheet to the other.

Below this is a lower grate of the usual

rocking pattern that burns only such

half-consumed fuel as falls through from

the upper grate.

In the operation of this type of boiler

all of the green coal is charged on the

water grate, and through this upper fire-

door the greater part of the air is ad¬

mitted, forming a draught down through

the green coal and carrying its smoke

through.the live fire and into the large

combustion chamber where it is entirely

consumed by the heat^ of the lower

fire which is fed by the coked live coals

which fall between the wide openings

of the water grate. The combustion

chamber back of upper grate is large

and high, giving the smoke a low veloc-

(■^AfeTrSaKL-V^

Steam P\pe

Mam HOLE 10 «^4"

^ ' J-AYtiR OF MORT/^^

PRonT;gl.E-W\TlOK

CRoss3coTlon ThroucpH A-A

sr -

ilZ^TEtuR0l.l.fRS

1^ ° 1

LONt^lTlTUTDIMAL /5ECT0N

7>lroii»rt BoiLtK WITH PUKPMCC KHO 3ETTIM*

FIG. 1—BRICK SET SMOKELESS BOIIaER.

I I ^^ I "I

ei'«33"cr

Double

l>»R.rFiMnb

i^r

^